Solution overview

Key capabilities

- Work order management

- Preventive maintenance

- Asset tracking

- Capital planning & forecasting

- Floor plan visualization

Get the most value out of your assets

Increase performance, extend equipment lifespan, and reduce unplanned downtime with software-assisted planning.

Increase your team productivity

Automate technician assignments and dispatching. Empower your team with mobile to-do lists updated to reflect the latest priorities.

Gain critical insights into your operations

View historical trends on team efficiency and asset performance. Gain actionable KPIs to drive strategic decision making.

Maintenance software purpose-built for your needs

Automated assignment

Save time and resolve work orders faster by automatically assigning the technician best suited for the task.

Inspection checklists

Create step-by-step instructions for all your inspections, cleanings, and QA testing.

Inventory management

Track inventory used, get notified of low stock and measure usage costs.

Cost and labor tracking

Track total cost and time spent on each maintenance activity to view summary reports.

Downtime tracking

Record equipment downtime and uptime, and view total downtime summaries to inform decision-making.

Sensor alerts

Automatically dispatch maintenance staff following an equipment failure or water leak.

Central calendar

Manage maintenance tasks for your entire team, with individual to-do lists for each technician.

Vendor & contact management

Keep a directory of vendors, suppliers, and outside contacts for quick reference.

Communication threads

Consolidate emails, phone calls, and word-of-mouth conversations into a single communication thread.

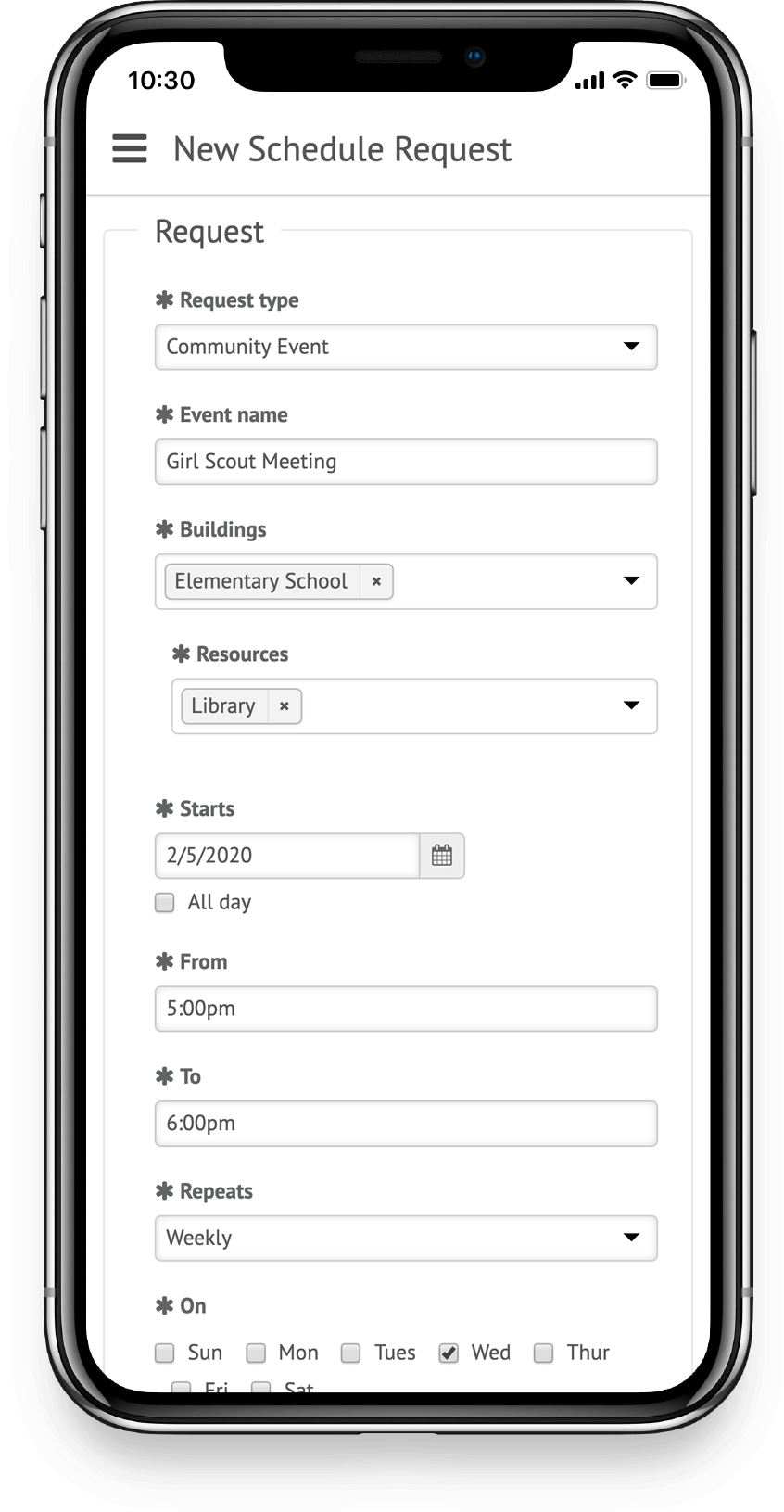

Full mobile CMMS access

Access the full FMX product on the go from your phone or tablet.

Want to see FMX maintenance management capabilities in action?

See it for yourself

Upgrade your maintenance toolset.

Related use cases

Work Order Management

Streamline maintenance request submissions and resolve issues while keeping track of labor hours and money spent.

Preventive Maintenance

Keep your operations running smoothly with a reliable preventive maintenance and inspection system.

Asset Mapping

Create a visual paradigm of your organization's equipment, inventory, resources, buildings, users, and other assets.

Equipment Maintenance

Reduce equipment downtime and increase the lifespan of your equipment and assets.

Inventory & Supply Management

Track usage, manage purchase orders, and get data insights into historical trends to optimize your inventory & supply management.

Facilities Management

Streamline day-to-day management processes into a simple and reliable system your whole team will love.

Reporting & Analytics

Capture, analyze, and discover actionable insights to optimize your organization's operations.

Thousands of maintenance professionals rely on FMX

FMX gives me capabilities I never had before. Now I can look at the equipment in each of our restaurants and verify the frequency and cost of every repair. Because the record keeping is so comprehensive, I can determine when a particular piece of equipment is no longer cost-effective and should be replaced.

$40K+ saved in the first 3 months

Gained valuable measurements to drive down costs such as technician route optimization and equipment replacement analysis.

Keeping track of preventative maintenance and repairs for 326 pieces of production machines and facilities equipment across 5 buildings was overwhelming before FMX. It is so much easier having a software solution that provides reminders, calendars, maintenance work orders, inventory management, and reporting all in one solution.

"It was overwhelming before FMX."

Trying to manage assets, buildings, and maintenance schedules without a coordinated system was overwhelming. FMX provided a single interface for managing everything related to maintenance.

All CMMS solutions are going to have similar functionality—take requests, monitor equipment, schedule routine maintenance, etc.—but FMX is by far the easiest to use, and their amazing customer support sets them above the rest.

50% reduction in work order resolution time

Transitioning from paper work orders to a digital maintenance management system that organizes work requests and provides updated to-do lists on each maintenance team member's iPad has reduced the time wasted resolving tickets.

Benefits of maintenance management software

Benefits of maintenance management software

- Extend asset and equipment lifespan

- Reduce unplanned downtime and delays

- Increase team productivity

- Meet necessary compliance and safety standards

- Gain critical insight to lower costs and improve performance

Making the switch is easier than you think.

Allow us to handle the heavy lifting.

We work with your team to transfer existing data and build workflows to meet your needs.

Empower your team with an easy-to-use platform.

FMX is built with simplicity in mind, so anyone can use it and be successful.

We're here to help along the way.

Our team is here to train your organization, with lifetime support to answer your questions.

Frequently asked questions

How is FMX maintenance software priced?

Pricing is based on the number of users working on and closing out maintenance requests (or the number of students enrolled for public K-12 schools), and the features and integrations most important to their organization.

Is FMX a cloud-based or on-premise solution?

FMX maintenance management software is cloud-based.

Do you have a process to address audit recommendations and to ensure regulatory compliance with security policies and standards?

Yes, we work with customers to meet their security requirements to the extent that they align with the sensitivity of data that we store.

Does FMX integrate with other software?

Yes, we integrate with several software systems that will be ready for use out of the box. If we do not already have an integration in place, we offer services to set up an integration for your needs.

How frequently is FMX software updated?

Our software development process is iterative and lean, which means we can get changes out very quickly with minimal bugs. In fact, over the past year, we've released over 70 updates, averaging one every five days. Because we have a web app instead of a native app, these updates happen automatically and don't require a manual update from users.

What kind of customer support does my organization receive with FMX?

We are proud to provide lifetime support to customers on any of our paid plans. Each customer is given a dedicated account manager that meets with them on a regular basis to ensure maintenance management success.

Our average response time for support tickets is 30 minutes, and we are happy to report a 98% customer satisfaction rating.

How much training will my team receive?

FMX offers webinar training for all users on our paid plans. During this training, we demonstrate how to submit and close out requests, and configure your personal settings. We also offer onsite training and configuration professional services.

What does the implementation process look like?

The FMX team is highly involved in the implementation process for Premium customers. We work with customers to import data, set up workflows, configure permission settings and processes to your needs, and more. The implementation process can take as little as 2 weeks.

What is maintenance management software?

Maintenance management software can range from simple maintenance task and ticketing solutions to asset management systems with spare parts inventory management, preventive maintenance scheduling, and integrations with condition-based and predictive maintenance systems.

Maintenance management software is often referred to as a computerized maintenance management system (CMMS).