Computerized Maintenance Management Systems (CMMS)

Learn how a CMMS can take your organization’s maintenance management processes to the next level with centralized, cloud-based software packed full of of insights.

What is a CMMS?

A CMMS enables your organization to manage maintenance activities to ultimately increase asset productivity, decrease costs, and streamline processes.

Example calendar view of maintenance activities scheduled in a CMMS.

A CMMS offers these key benefits:

- Meet regulatory compliance and safety standards

- Lower maintenance costs

- Make data-driven maintenance decisions

- Increase productivity

- Extend lifespan of equipment

Features of a CMMS

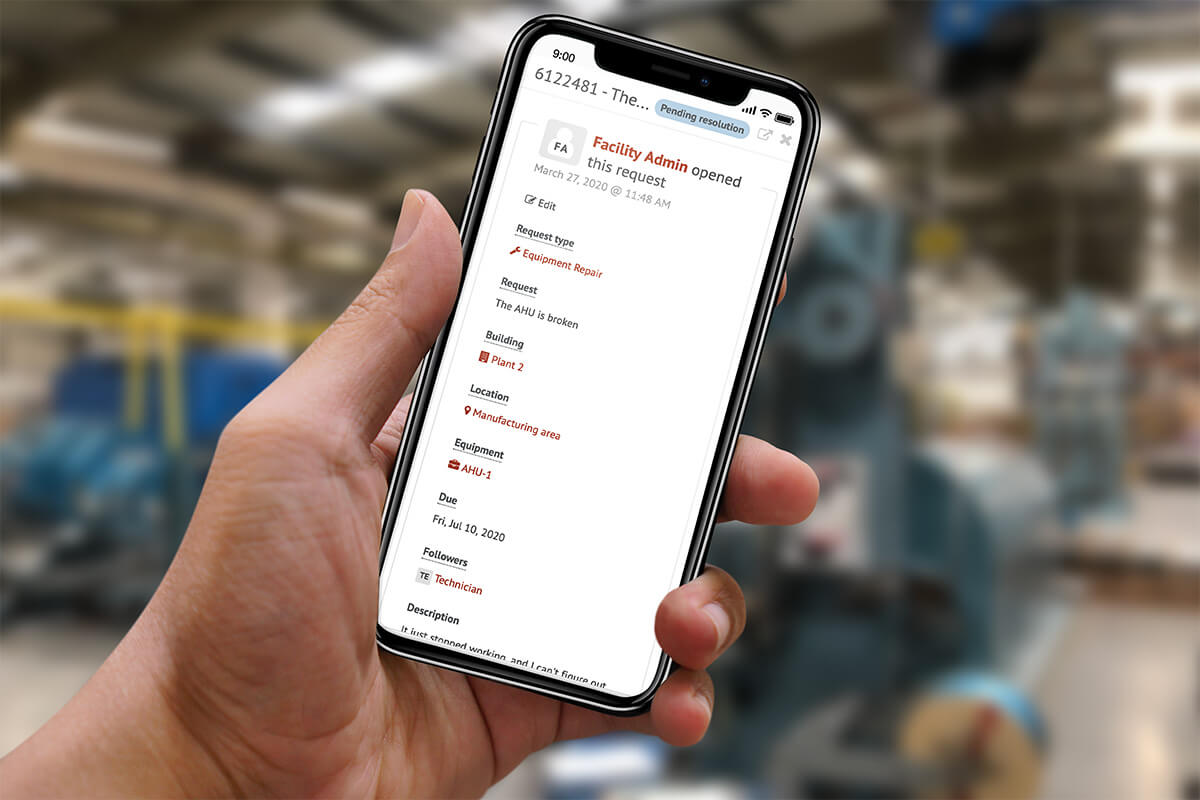

Work order management

Work order management software streamlines maintenance operations, leads to faster response times and resolution times, and ensures your team never loses work orders again.

You can set up your system to automatically prioritize and assign requests to the appropriate technicians so that your team can focus less on tracking work orders and more on repairing assets.

Preventive maintenance management

With the preventive maintenance software feature of a CMMS, you can schedule PM tasks proactively for your equipment and assets.

This prioritizes preventive work for your team, sends notifications reminding them when an equipment item is due for maintenance, and ensures that no task is overlooked.

Parts and maintenance inventory management

Maintenance inventory management software ensures parts and supplies are available when equipment needs attention. A successful system will allow you to track inventory items when working on maintenance tasks so that your inventory levels are kept up-to-date in real time. The system will even alert you when an item is reaching its reorder point.

Most importantly, a CMMS can help you strike that balance between reducing inventory shortages and minimizing unnecessary storage costs from overstocking parts and supplies.

Asset and equipment maintenance

Equipment maintenance software allows your team to track all of the assets in your facilities, including equipment, vehicles, and more.

Information such as purchase price and date, serial number, manuals, warranties, and a history of maintenance work performed is all stored in the CMMS.

Reporting and analytics

A CMMS can provide reports for tracking your organization’s most important key performance indicators (KPIs).

You can analyze these reports and use the data to fuel decisions, showcase returns on investment, and allocate resources appropriately.

The role of CMMS is ever-expanding as vendors incorporate more integrations, automations, and workflows. See more CMMS features.

History of CMMS

Initial versions of the CMMS date back to the 1960s, but these systems were much different than what’s available today.

In 1965, maintenance management systems consisted of large mainframe systems using punch cards to input data about maintenance tasks. Because IBM mainframe computers were very expensive at this time, CMMSes were only available for enterprise organizations.

In the 1970s, the process changed slightly. Technicians now filled out paper work order forms. The information from the paper form would be scanned or entered into the mainframe computer to track daily tasks.

It wasn’t until the 1980s—and the introduction of the mini-computer—that small- and mid-sized organizations could afford CMMS software. With access this new technology, technicians were able to submit their own work orders on computers that were dispersed throughout each facility. Once personal computers became available in the 90s, many homegrown systems became available. These typically ran on a server maintained by the company’s IT department, and they were accessible from anywhere within the facility.

At the turn of the century, CMMS solutions became web-based over corporate intranets and the Internet. This introduced greater connectivity for a larger range of devices spread geographically across multi-site networks.

In the latest generation, CMMS vendors adapted their solutions to largely be cloud-based and mobile. This gives organizations the ability to manage maintenance anytime, anywhere, on any device—and do so more reliably with lower IT overhead.

Benefits of CMMS

Benefits of CMMS include meeting compliance and safety standards, lowering maintenance costs, making data-driven maintenance decisions, increasing productivity, and extending lifespan of equipment.

Lower maintenance costs

Reports generated by a CMMS system allow you to track maintenance, labor, and inventory costs in one user-friendly system.

Extraneous costs and labor hours can be associated with work orders, preventive maintenance tasks, inventory updates, and more to provide a holistic, real-time view of your facility management and maintenance expenses.

You can use this data to gain insight into problem areas within your department—while discovering ways to justify investments, cut costs, and improve your bottom line.

Make informed, data-driven maintenance decisions

The data collected in your CMMS software is extremely customizable and powerful. It can be used to justify capital and labor expenditures, determine when to repair an equipment item versus when to replace it, discover bottlenecks in your processes, and more.

By detailing the number of maintenance repairs, labor hours, equipment downtime, and inventory costs, you can identify the resources your team needs to operate efficiently.

Extend lifespan of equipment and assets

Routine inspections allow your team to identify problems with equipment and assets before they cause disruptions in your workflows. In addition, broken or worn parts can be replaced before causing unnecessary damage to the rest of the asset.

This extends the useful life of your equipment and reduces the frequency of unexpected breakdowns.

Reduce equipment downtime

By scheduling and tracking preventive maintenance, you are ensuring each asset receives the proper care it needs—and ultimately reducing equipment breakdowns.

In addition, the system can predict the next time a piece of equipment will break, allowing you to perform preventive maintenance before it fails.

Increase productivity

Organizations that implement a CMMS typically see an immediate increase in productivity. Work order response and resolution times decrease, and less time is spent managing requests, This means that technicians can get more work done.

Less time, more work—that’s maintenance management productivity at its finest.

Streamline processes

A CMMS automates processes like never before:

Work requests can be routed to the appropriate technician in real time. When a work request is being worked on, updates are sent to the requesting user letting them know of its progress.

The ability to attach pictures and documents to work orders leaves little room for ambiguity, requires less back and forth between requesting users and technicians, and allows your team to resolve maintenance requests faster.

Meet compliance and safety standards

A CMMS keeps an extremely thorough record of all the maintenance that has been performed on each piece of equipment. Your maintenance team can access these reports to verify compliance and safety regulations are being met.

In addition, CMMS software can store important information, such as product requirement documents and manufacturing build packages, for easy access to these materials.

Certain jurisdictions have industry-specific requirements like OSHA and Title 21 CFR Part 11—all of which proper use of a CMMS can help provide the appropriate digital paper trail to satisfy.

Increase labor efficiency and team performance

A CMMS system can track the amount of labor spent performing maintenance by technician, equipment item, or work order.

This information allows you to identify weaknesses in your processes so that you can address and improve them, ultimately increasing efficiency.

Read the 17 benefits of a CMMS

Difference between a CMMS and EAM

Computerized maintenance management systems and enterprise asset management (EAM) systems are often mistaken for one another, and understandably so. Both focus on asset management but do so in different ways.

A CMMS enables you to manage day-to-day maintenance activities to ultimately increase asset productivity, decrease costs, and streamline processes, while an EAM only focuses on asset management.

While EAM software’s asset management capabilities are more robust, it isn’t a holistic solution that manages all of your maintenance activities like a CMMS.

What to consider when researching CMMS software

Cloud-based

Choosing a cloud-based CMMS opens up a world of benefits for you and your team. Web-based and cloud based CMMS systems allow you to work anytime, anywhere, on any device, and they typically have a less expensive initial setup.

In addition, the implementation is typically quicker and easier than an on-premises option, and updates are made available automatically with no manual software updates required.

Flexible

Flexible CMMS systems allow your team to dictate what matters most, so that you have all the features you need—and none that you don’t.

You should choose a CMMS system that allows you to create reports for the metrics that matter most to your team, and name the resources and locations in the system to match your organization.

A CMMS should adapt to fit your unique processes, not the other way around.

Easy to use

In order for you to gain the most out of a CMMS, people need to actually be able to use it, which makes ease of use extremely important.

When users log in into the maintenance management system, they should be able to create a work order without any training. A simple interface allows anyone in your company to submit a request—and then track its progress—for optimal efficiency.

The more the system is adopted across your organization, the better the results your department will achieve.

Implementation

Be sure to ask about the implementation process and what is required of you versus what the CMMS provider is responsible for.

If the has a guide to walk you through the implementation process, common roadblocks, and how to overcome them, that’s a signal that you’ll have the appropriate foundation for success.

Support

A team that is ready to support you as you navigate a new software package is crucial to your success.

Questions will arise and issues will occur, but if you have a support team that’s ready to help you tackle all of your facility and maintenance goals, you will run into minimal (if any) bumps.

When conducting research, ask what happens in the case of an emergency if it’s outside of support hours, what the average response time is, and what their customer satisfaction rating is. Answers to these questions will help you choose the solution that puts your needs first.

How to choose CMMS software

1. Determine maintenance needs and goals

In order to choose the solution that works best for you and your team, it’s important to lay out your objectives. Establishing these up front will help you prioritize solutions with your organization’s maintenance goals in mind.

You should consider define your goals in these areas:

- return on investment

- cost savings

- time savings

- improvements in efficiency

- compliance needs

- downtime objectives

- safety improvements

- parts, supply, and inventory management

- preventive maintenance

Once these are outlined, you can begin to determine what your solution looks like.

2. Evaluate vendors

Once you’ve established your goals, you can begin to compare vendors. Eliminate the vendors that are unable to meet the majority of your goals, and narrow your choice down to a handful of candidates who can meet all, or most of, your maintenance needs.

You should also evaluate the implementation services and support from each vendor. These services set you up for success and ensure you’re equipped with everything you need to manage your maintenance.

3. Choose a solution

After you have it narrowed down to a few options, schedule demos with your shortlist of vendors. A product specialist will be able to answer all of your questions and let you know if their product can help you achieve your goals.

You should also create a decision matrix analysis that houses a set of criteria that you’d like each vendor to meet. Rate these criteria on a scale of 1–10 based on how important each one is to you. Then rate each vendor’s ability to achieve that criteria on a scale of 1–10. Simple math will allow you to determine which vendor is best suited for you.

4. Make the case to the decision makers

To make the case for a CMMS, you first need to outline the drawbacks of your current system. What’s not working, and why does this warrant a change?

Next, share the goals of the project. If you have an idea of what great looks like, this will motivate decision makers to help you achieve it. Discuss your preferred vendor and how they will help you reach those goals.

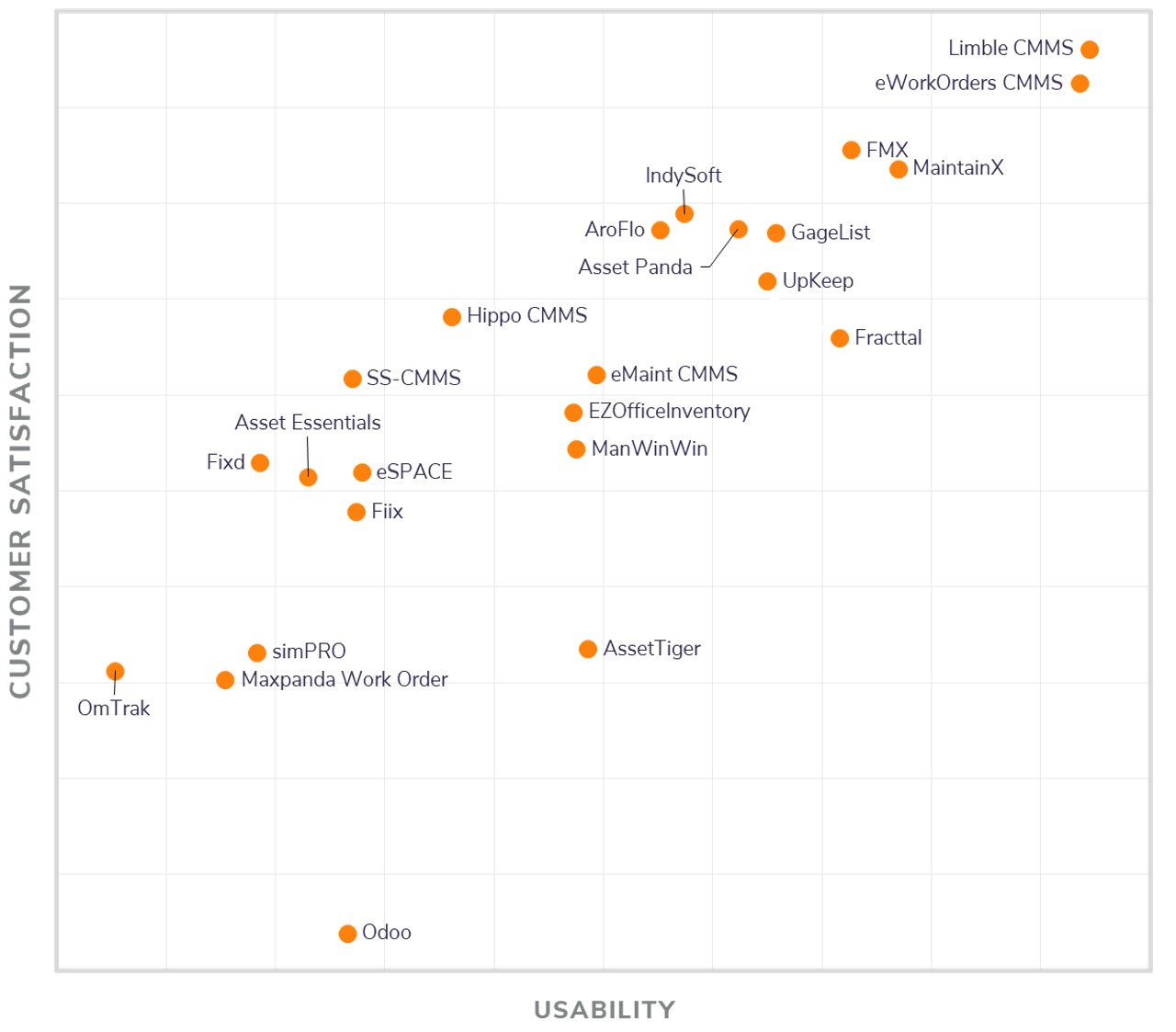

CMMS vendor comparison

The CMMS Software FrontRunners quadrant on Software Advice by Gartner highlights leaders in usability and customer satisfaction in CMMS software.

Source: Current FrontRunners quadrant in the Top CMMS Software category, February 2021, Software Advice by Gartner.

According to customer reviews submitted on popular review sites Capterra and Software Advice, this is how top CMMS systems compare across key categories.

| FMX | eMaint | UpKeep | Dude | Fiix | |

|---|---|---|---|---|---|

| Functionality 2 | 4.5 | 4.5 | 4.5 | 4.0 | 4.0 |

| Customer support 1 | 4.9 | 4.5 | 4.8 | 4.6 | 4.4 |

| Value for money 2 | 4.6 | 4.5 | 4.5 | 4.0 | 4.5 |

| Ease of use 1 | 4.6 | 4.2 | 4.6 | 4.1 | 4.3 |

Overall 3

|

4.66 |

4.41 |

4.66 |

4.26 |

4.42 |

|

Sources:

- 1 Capterra

- 2 Software Advice by Gartner

- 3 Average score based on both review sources

Simple, configurable CMMS software

Learn more about FMX, the top-rated CMMS solution designed to help you manage maintenance, schedule preventive work, and more.

More CMMS resources

- Maintenance Management Guide

- Maintenance Management Software

- Benefits of CMMS Software

- CMMS Features and Functionality

- 7 Reasons to Switch from a Paper-Based System to a CMMS

- Excel vs. CMMS: 7 Reasons You Should Switch to CMMS Software

- The Hidden Costs of Delaying Your CMMS Project

- On-Premise vs. Cloud-Based CMMS

- 5 Wins Manufacturers Can Achieve with a CMMS

- CMMS for Small Business

- Comprehensive Guide to CMMS Implementation

- Achieving Title 21 CFR Part 11 Compliance

- 3 Reasons for CMMS Software Failure and How to Prevent Them

- 8 CMMS KPIs Your Organization Should Be Tracking

- 13 CMMS Best Practices