Table of contents

What is a maintenance backlog?

Every maintenance department has work orders they put on hold for various reasons. The maintenance backlog is a list that catalogs all on-hold maintenance work that needs to be completed.

A maintenance backlog helps manage a maintenance team’s time and workflow. It can calculate and prioritize jobs that should be tackled first and which can wait. Preventive and corrective maintenance tasks, deferred maintenance, and inspection items make up the maintenance backlog.

The maintenance backlog is unavoidable. Every maintenance department has one. It’s a good part of the maintenance process but is an item that should be tracked and managed as much as parts inventory or employee work hours.

Why is the maintenance backlog important?

The most evident reason why the maintenance backlog is essential is to ensure a maintenance team does not lose sight of maintenance tasks that were postponed. Neglected or deferred maintenance can often lead to an increase in more severe breakdowns and possible injury. Safety is always a top concern. Compliance can also become an issue if an asset isn’t inspected and reported on promptly to a regulatory authority.

The maintenance backlog is also an indicator of time management and maintenance planning. Are crews performing at an optimal level to complete work requests? Are maintenance tasks explained in a way that makes sense? The maintenance backlog can identify workflow, communications, and efficiency problems.

In addition, the maintenance backlog shows the health of the maintenance department. Is it overworked? Do you need more staff? Is a department under-resourced? A longer maintenance backlog is a strong indicator of all three and can provide data on ways to improve a maintenance manager’s department and team.

How much maintenance backlog is too much?

Although the calculation is different for every organization, a maintenance backlog of two weeks is generally sufficient for a maintenance department. It could increase for departments with a continuous workflow cycle of preventive maintenance and predictive maintenance tasks. In those cases, three to four weeks is typical.

The calculation’s iteration depends on many factors, but most importantly, the productivity of each member of your team of maintenance professionals. A computerized maintenance management system (CMMS) can help determine an employee’s productivity with advanced labor tracking and automated maintenance work order assignment.

How to calculate the maintenance backlog

Time is of the essence, as they say, and that’s the statistic we need to bring priority and efficiency to our maintenance backlog management.

A basic backlog calculation takes the total number of work hours needed (completion time) to complete a repair or backlogged maintenance task and divides it by employee hourly completion rates (completion rate). This analytic can determine the time necessary to complete backlog work items (time required). Add that number to the final calculation of each task that needs attention, and you have the total number of hours required to fulfill the backlog maintenance list.

The formula looks like this:

Completion Time / Completion Rate = Time Required

Keep in mind, this number will fluctuate wildly and ebb and flow as new work arrives or scheduled tasks pop up on the entire maintenance operation’s work schedule.

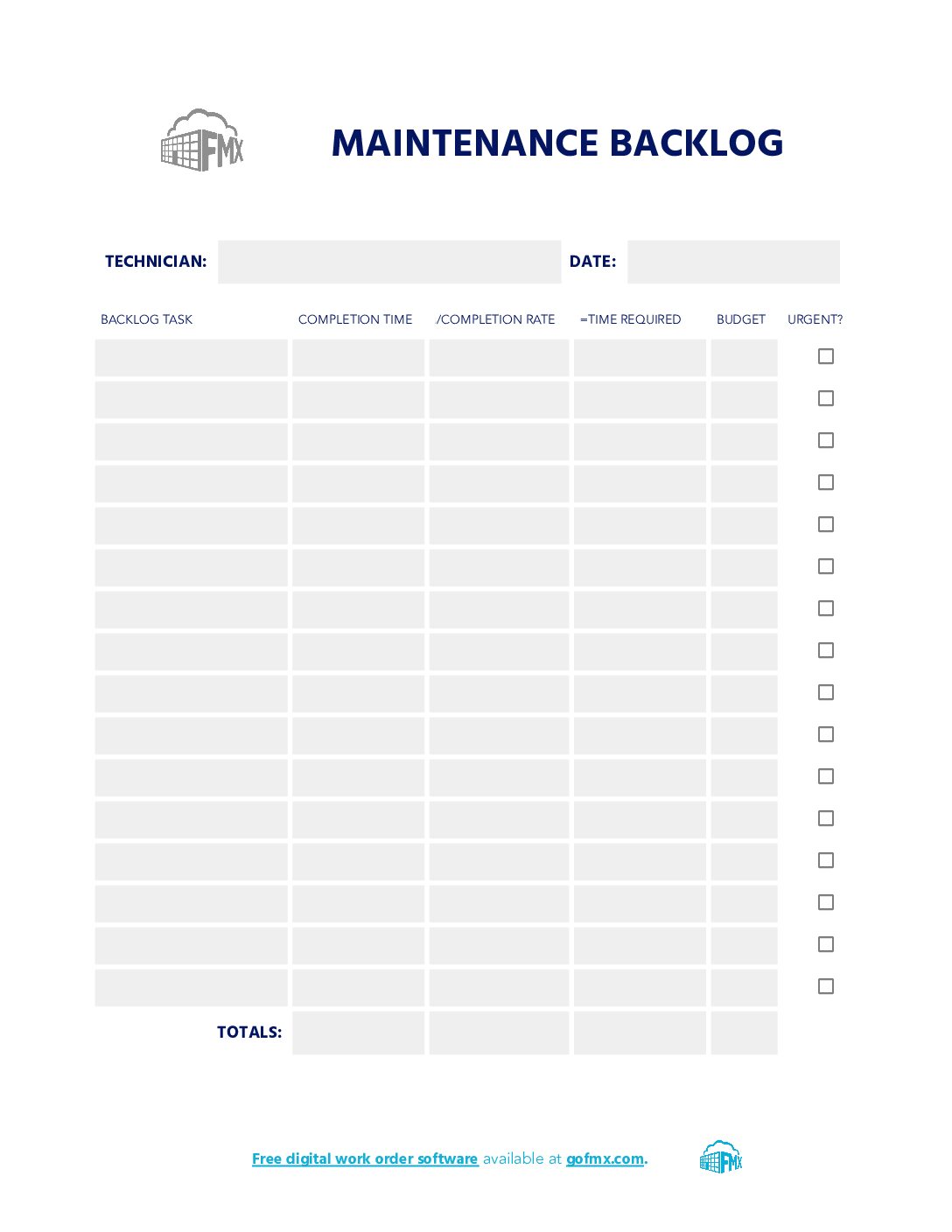

FMX has put together a maintenance backlog template you can use for free to help prioritize and organize backlog management. It also includes lines for estimating costs and budgets for continuous improvement.

Maintenance Backlog Template

Use this free template to prioritize and organize your maintenance backlog, including lines for estimating costs and budgets.

Managing the maintenance backlog with CMMS software

While a maintenance backlog template is a big help, a maintenance management software like FMX can be of even greater value. A CMMS can keep track of a facility’s work orders and work hours needed to complete a maintenance backlog item. And as stated previously, it can track the maintenance activities and productivity of employees.

Having the data available in an easy-to-use dashboard can save maintenance departments more time as the maintenance backlog decreases into more manageable levels. A CMMS allows you to see more choices available for work competition and how best to facilitate effective results.

Summary

Managing the maintenance backlog is a necessary function of all maintenance departments and maintenance managers. It helps address asset longevity, safety concerns, compliance issues, department time management, and a growing maintenance backlog.

A CMMS can help increase analytical data and deliver a higher view of prioritization. Planning, scheduling, and resource management will allow managers to get a grip on maintenance backlog management.

Learn how FMX’s maintenance management software can help you gain control over your maintenance workload.

Written by

Dean Heid

Content Manager at FMX