Predictive Maintenance

Predictive maintenance (PdM) is an increasingly popular strategy for facility management leaders. Learn why and learn how to set up a successful PdM strategy.

What is predictive maintenance?

Predictive maintenance is a maintenance strategy that uses advanced downtime tracking software to analyze data and anticipate when maintenance should be performed on your equipment. With PdM, software constantly monitors your equipment’s performance and machine health using sensors. When performed correctly, these sensors alert you when equipment is nearing a breakdown so that you can perform maintenance before any unscheduled downtime occurs.

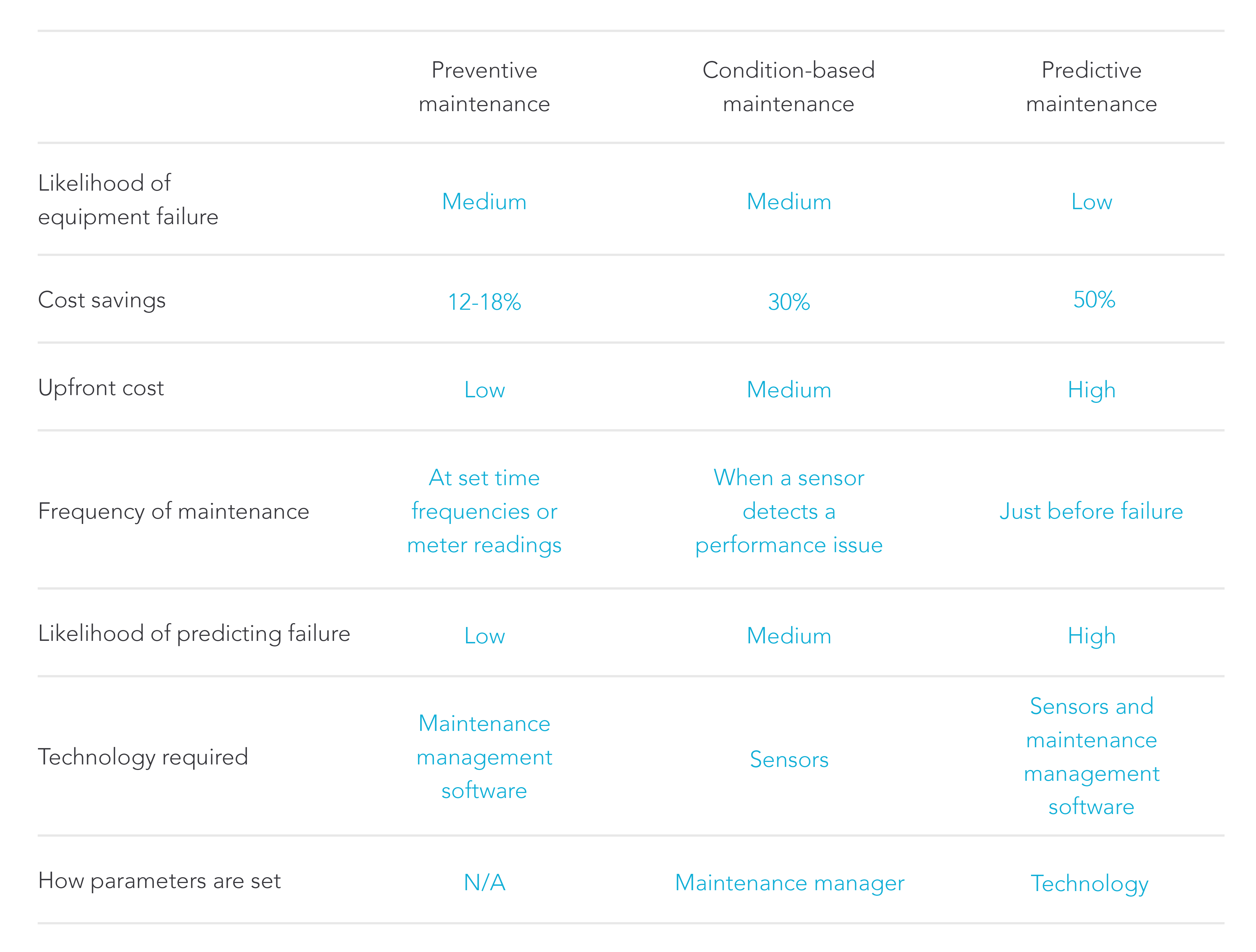

PdM is the preferred maintenance management method for many organizations. While preventive maintenance and reactive maintenance can become costly in the long run, predictive maintenance lowers that cost with upfront investment.

How does PdM work?

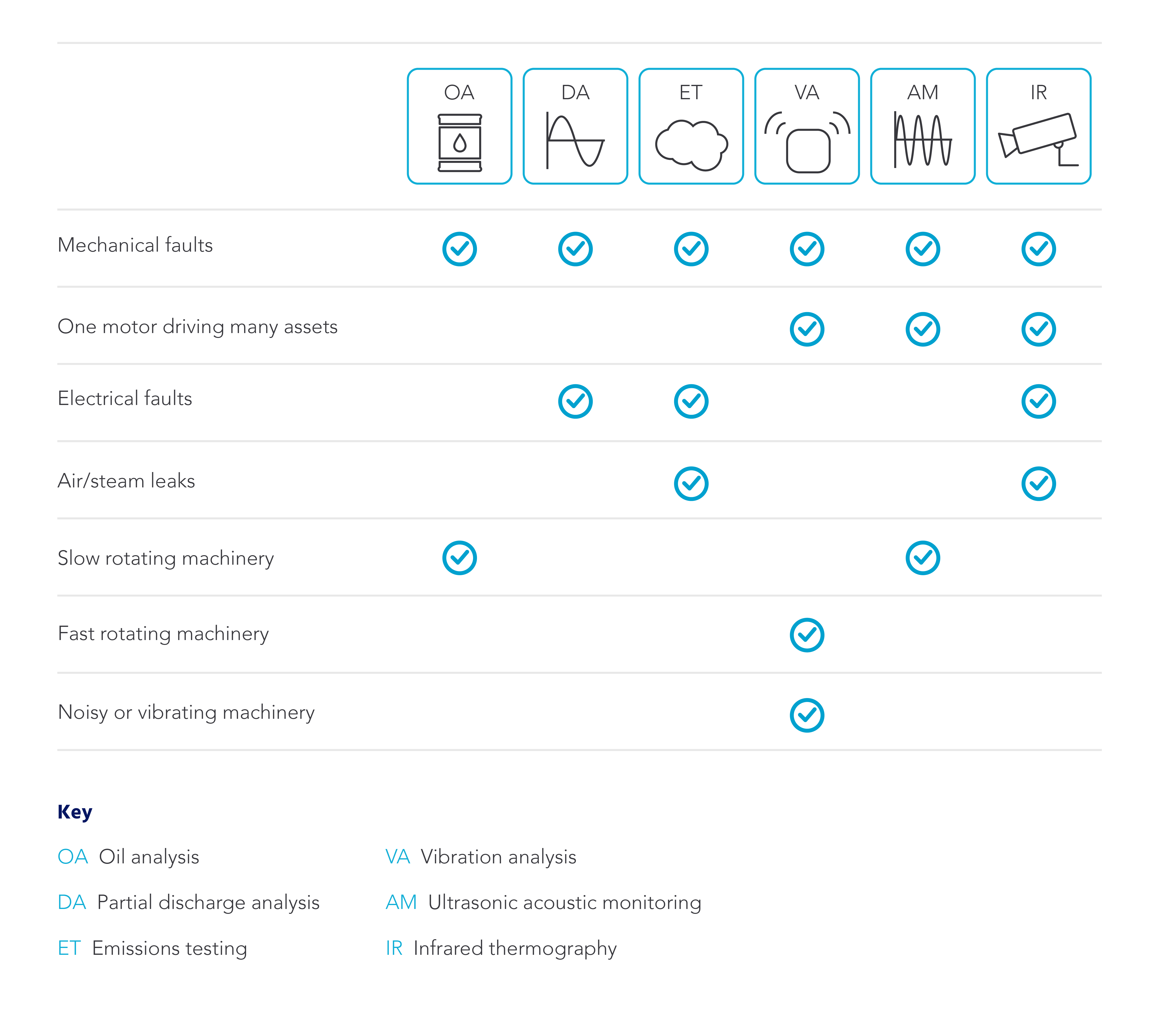

A successful predictive maintenance program is highly dependent on the Internet of Things (IoT) and condition-based monitoring equipment. Condition monitoring equipment (infrared thermography, acoustic monitoring, vibration analysis, etc.) is used to analyze an asset’s performance in real-time. IoT embeds objects with sensors that allow a seamless exchange of data between these objects and systems across the Internet.

Together, condition monitoring equipment and IoT allow sensors placed on equipment to connect to one another and exchange data in real-time. As this data “talks” to each other, it recognizes trends and sets parameters for performance. When a sensor detects spikes or dips falling outside of these parameters, it alerts your team that that equipment is nearing failure.

The image below outlines a typical predictive maintenance workflow.

Typical predictive maintenance workflow

Benefits of predictive maintenance

With real-time equipment data syncing to your maintenance management system, you’re able to react to any sensor data fluctuations right before that asset fails. In other words, you’re able to prevent equipment from breaking down just-in-time. Its predictive analytics leads to significant improvements in reliability, availability, and operating costs.

More reliable equipment

Reliability is the probability that equipment will meet certain performance standards in a certain timeframe. Mean time between failures (MTBF) is a metric often used to measure reliability and can be calculated as follows:

MTBF = (time asset has been in use – unplanned downtime due to breakdown) / total number of breakdowns

Plants that implement predictive maintenance processes see a 30% increase in equipment MTBF, on average. This means your equipment is 30% more reliable and 30% more likely to meet performance standards with a predictive maintenance strategy.

More available equipment

Availability is the percentage of time that equipment is operated under normal circumstances. Also known as uptime, availability can be calculated as follows:

Availability = (total planned operating time – sum of unplanned downtime) / total planned operating time

In a survey of 500 plants that implemented a predictive maintenance program, there was an average increase in equipment availability of 30%. Simply implementing PdM will ensure your equipment is running when you need it to run.

Overall decrease in operating costs

With a successful PdM plan in place, your team will spend less time and effort maintaining equipment, you will use fewer spare parts and supplies for unplanned maintenance, and you will incur fewer breakdowns and equipment failures. All of this is money back in your pocket. In fact, it’s as much as double the money in your pocket. On average, predictive maintenance reduced normal operating costs by 50%.

However, PdM isn’t always the right solution for every organization. While the return on investment (ROI) for predictive maintenance is very high, the upfront costs can be steep and should be taken into serious consideration.

Predictive maintenance technologies

As mentioned earlier, predictive maintenance relies heavily on the use of sensors to monitor each asset’s performance. Fluctuations in sensor data that fall outside of normal parameters will alert you to attend to that asset and take action before failure occurs.

You can implement the following condition monitoring techniques to catch issues just-in-time and minimize asset failure.

Infrared thermography

Infrared thermography is a method that detects infrared energy released from an asset, converts it to temperature, and displays an image of how temperature is dispersed over time for that particular asset. As components of your equipment become overused and worn, they tend to release more energy than normal. This results in higher temperatures and “hotspots” that appear on the infrared image.

These hotspots are quite easy to identify, which makes infrared thermography a popular predictive maintenance technology.

Vibration analysis

Vibration analysis is the process of measuring vibration levels and frequencies of equipment to determine the performance of an asset and its components. This can be done using a handheld device called an accelerometer, but for the purposes of predictive maintenance, it’s best to install sensors on your assets. The vibrations detected from the sensors are then fed into a data collector that presents the vibrations in the form of a time wave (amplitude vs. time), a Fast Fourier Transform (amplitude vs. frequency), or both.

Equipment that is operating at peak performance will have different vibration patterns compared to equipment that isn’t performing as well. These patterns are analyzed to determine the performance of each equipment item and to detect problems such as lubrication errors, misalignment, loose components, and more.

Ultrasonic acoustic monitoring

Ultrasonic acoustic monitoring utilizes sensors to detect sounds caused by the rubbing together of components within a bearing. The sounds produced by worn and under-lubricated equipment are not detectable by the human ear, but sensors are able to detect these high pitches and transform them into visual or audible alerts for maintenance teams.

Oil analysis

An oil analysis can provide insight into the health of your assets’ engines and alert you to issues before they lead to equipment failure. The analysis studies the oil in your equipment and looks for water particles and other liquids, contaminants, and even small bits of metal. The presence of these particles in your oil may mean there is a leak somewhere or your equipment is wearing.

One of the reasons many organizations utilize this strategy is because it’s very easy to create a baseline and parameters for your oil when you purchase new equipment.

Emissions testing

Emissions testing evaluates the level of air pollutants emitted from the exhaust of a piece of equipment or motor vehicle. During inspections, the sensors are looking for levels of hydrocarbons, nitrogen oxide, carbon monoxide, and carbon dioxide. If the exhaust is producing excess pollutants, your team should take steps to understand and remedy the issue.

The cause of excess air pollutants varies from faulty fuel injection to a broken air injection system to oxygen sensor malfunction and ignition system defects. An emissions test allows your team to discover the root cause of the issue before failure occurs.

Partial discharge analysis

Partial discharges are small electrical sparks that appear in the electric insulation of switchgears, cables, transformers, and windings in large motors and generators. Similar to other analyses, parameters can be set for these discharges and any measurements that fall outside of these will create alerts for your team.

Partial discharge analysis is used to predict which electrical equipment is in need of maintenance and close to failure.

Steps for establishing a predictive maintenance program

1. Analyze historical data and identify critical assets

Before beginning your predictive maintenance journey, it’s important to analyze your current equipment. Review any instances of downtime, defects, and audit fines and take a close look at the preventive and reactive maintenance performed on each asset.

You can then use insights from your analyses to rank your assets by criticality. This is a fundamental step when establishing a PdM plan. It’s unlikely that you’ll be able to implement predictive maintenance for all equipment items, so you need to determine which ones take priority.

Assets with high and frequent maintenance costs that are imperative to the success of your operations should receive a plan first. Once these are taken care of, you can begin to create plans for the rest of your equipment.

2. Install IoT sensors

IoT sensors are the foundation for predictive maintenance success. Without them, you’ll be relying on preventive maintenance tactics to dictate when to check on your equipment. There are several differences between these strategies, which are outlined later in this guide.

When applying sensors, be sure to put some time, research, and thought into which predictive maintenance technologies and predictive algorithms outlined above are right for each asset. For instance, infrared thermography is best used on equipment that may leak air or steam while vibration analysis is best used on rotating equipment, but not equipment that rotates slowly (less than 5 rpm). Oil analysis and acoustic analysis are better for slow rotating equipment.

Understand how your equipment works and operates to make informed decisions on the sensors to install. While some assets may have only one sensor, others may have several that are required to accurately predict failures.

The last aspect of this step is hooking these sensors up to other systems for accurate data collection and analysis. It’s imperative that information collected by the sensors is sent to the technology you use to analyze equipment health and performance. This allows you to react quickly to maintenance concerns.

3. Establish equipment parameters

As your equipment runs, and the sensors collect readings, the technology in place will begin to realize patterns and trends in the data. It will then create a prediction model for your equipment that sets parameters for when an asset is likely to fail.

As more data begins to collect for your equipment, these parameters will become so accurate that even the smallest change in performance will indicate that a failure is likely to occur. This will trigger an alert to your team notifying you that it needs to be inspected and maintained immediately.

4. Set up action items when alerts are triggered

Your sensors will record data that falls outside of your set parameters. When this happens, you need to have a plan in place that details who is in charge of performing maintenance, which steps need to be taken for each individual sensor, and days/times of preferred maintenance. Outlining these steps ensures proper action is being taken to remedy the problem and that equipment is being worked on outside of normal operating hours.

5. Ensure you have proper systems in place

Detecting deficiencies in your equipment is only one piece of the puzzle. You need to have a way to react to these issues, dispatch them to your team, and ensure inspections and maintenance are being performed correctly. Without this, you’ll find that you’re able to recognize errors but won’t be able to take immediate action to remedy the problem. Equipment failure will likely still occur, which means your initial work and investment have been for nothing.

CMMS software connects to your sensors to create, assign, and manage a work order every time a sensor detects a reading outside of parameters. This streamlines the entire predictive maintenance process, ensuring the right people are assigned the right task and that they have all the necessary details to assess, and fix, the equipment successfully.

PdM applications

Organizations have started recognizing the benefits and hefty return on investment of a predictive maintenance solution, and are adopting it worldwide. According to Market Research Future, the global PdM market is expected to expand to 23,051.4 million in 2025, and there’s a good chance it will only increase from there.

While any organization with heavy equipment can benefit from a predictive maintenance strategy, the manufacturing industry has seen a tremendous amount of success after implementing PdM. With high production needs, quick turnaround times, and frequent audits and inspections, manufacturers need to ensure their equipment is as available and reliable as possible. Predictive maintenance gives manufacturers the ability to increase throughput and productivity, increase safety for their technicians, and decrease equipment downtime significantly.

The Industrial Internet of Things’s (IIoT) artificial intelligence allows for even more success. Manufacturing maintenance software dashboards and analytics can integrate with your sensors and give your team real-time updates on production levels, lubrication, performance for different equipment components, and more. In general, manufacturing organizations see a 55% decrease in unplanned equipment failures after implementing PdM. After factoring in the effect this has on production rates, employee time savings, and spare parts inventory usage, this will lead to thousands of dollars in savings.

Predictive maintenance vs. other maintenance strategies

While predictive maintenance is successful for many organizations, it isn’t the right strategy for all. Predictive maintenance is known for its steep upfront costs, and while the return on investment is quite large, not all maintenance teams have a budget that’s flexible enough for this cost structure.

There are less costly options though! While other maintenance methods don’t offer all the benefits and insight into your equipment as PdM, they offer a plethora of capabilities that work perfectly fine for many organizations.

Preventive maintenance

Preventive maintenance is the most widely adopted form of proactive maintenance. This is because it’s relatively easy to get up and running, and offers a lower upfront cost than predictive or condition-based maintenance strategies.

Similar to PdM, preventive maintenance focuses on sending out a maintenance team to perform maintenance before equipment fails or malfunctions. However, the way in which preventive maintenance is scheduled is extremely different from PdM. As explained above, with predictive maintenance, the software continuously analyzes equipment performance by monitoring sensors and technology. Maintenance is scheduled when a sensor detects performance outside of normal parameters. On the other hand, preventive maintenance is scheduled based on set time intervals or meter readings.

Because preventive maintenance is scheduled to occur no matter the performance of your assets, you may find yourself inspecting and maintaining equipment more often than you need to. Over time, this leads to unnecessary time and money expenses. While PdM has significantly higher upfront costs due to sensor and technology purchases, in the long run you’ll see less time and money spent maintaining these assets than with preventive maintenance.

Read more about preventive vs. predictive maintenance.

Condition-based maintenance

Condition-based maintenance is a very close cousin of predictive maintenance, and the two are often mistaken for one another. So, what is condition-based maintenance and how does it differ from PdM?

Condition-based maintenance is maintenance performed on your equipment when there are indications of a reduction in performance.

Pretty similar to PdM, right?

Both of these strategies rely on sensors to assist in determining performance. However, while predictive maintenance is able to analyze sensor readings to predict failures in the future, condition-based maintenance cannot. It is only able to tell if something is wrong in the moment.

One of the main reasons for this is that predictive maintenance utilizes very advanced statistical methods, like machine learning, to determine when a machine is reaching a point of failure. Software analyzes readings from all sensors and creates one prediction model. Because of this, the more sensors and available data for the system to analyze asset health, the better your system will become at predicting future breakdowns.

On the other hand, condition-based monitoring requires people to analyze each individual sensor’s data and look for deviations from the norm. Instead of technology driving your points of failure, you must set these limits yourself. Setting an upper control limit and a lower control limit gives your machine a lot more “wiggle room” for failure than predictive maintenance. Check out the graphics below to see the difference between these analyses.

An equipment item’s performance readings using condition-based maintenance

An equipment item’s performance readings using predictive maintenance

As opposed to condition-based maintenance, predictive maintenance allows you to detect even the smallest changes in performance so that you can better analyze and predict failures. Like mentioned before, this technology comes at a cost though. Condition-based monitoring relies more on human intelligence and senses and therefore comes at a lower implementation cost. In fact, you can get this strategy up and running by installing one sensor for a piece of equipment and monitoring its performance.

While this strategy is more advanced than preventive maintenance, it lacks the ability to predict equipment failures like PdM. If the success of your organization is highly dependent on your equipment performing its best at all times, a predictive maintenance program is better suited for your needs.

Conclusion

Predictive maintenance has become an extremely popular maintenance strategy for facility managers over the past decade and continues to increase in popularity. Organizations that take advantage of PdM are seeing significant savings in cost, and more reliable and available equipment. If you’re thinking of implementing a predictive maintenance program for your equipment, it’s important to first establish a plan and put the right sensors and technology in place. While it may seem like a costly investment to measure asset condition, the return your team sees will be worth it.

Want to learn more about predictive maintenance?

Get predictive maintenance tips and maintenance industry updates from FMX in your inbox.