Table of contents

Maintenance management plays a key role in supporting the production process and ensuring it can continue uninterrupted. To do so, managers have to handle a wide scope of activities, from preventive, corrective, or planned maintenance.

Strong management software coaligned with thorough, updated standard methods are two main components necessary for a successful, happy maintenance staff. Let’s take a closer look at how to ensure your organization can develop and write successful maintenance procedures.

Why are maintenance SOPs important?

Standard operating procedures (SOPs) are sets of guidelines or instructions that need to be followed to make sure a process is done correctly every time. A maintenance SOP will streamline workflows and ensure industry quality control while allowing employees to become comfortable with the predictability of their jobs. Yes, unexpected repairs will be inevitable. However, SOPs will also provide employees and management with the appropriate actions to take in each scenario — and can be updated to include the most efficient maintenance procedures as situations arise.

A well-written SOP manual includes detailed instructions for an employee on how to do their work. It’s a living document that will change as the organization evolves.

The benefits of having a maintenance SOP manual include:

- Helps with safety

- Ensures quality and accuracy

- Facilitates warranty compliance

- Encourages accountability

- Provides consistency

- Improves time management

- Reduces mistakes and errors

- Maintains efficiency

Properly structuring your SOP content is a vital part of ensuring that your team remains on the same page with the many maintenance procedures on-site.

Coordinate maintenance from a single interface

Schedule work, track assets, and leverage data-driven insights to optimize your maintenance operations.

Structuring a standard operating procedure

An SOP can be used to standardize tasks and provide clear instructions for those who are asked to perform them. To create an effective SOP, you must first identify the objective of the job, as well as potential hazards that may be present.

From there, identify all of the steps required to complete the task in a safe manner. And finally, include any safety equipment that will be required during its completion. In some cases, your SOP will also include the average time in which it should take to complete the assignment (this will help with scheduling and prioritization).

A maintenance SOP should be detailed enough to ensure all the necessary steps are followed. However, it shouldn’t be too long or complicated. The goal is to have technicians understand each step without needing to spend a disproportionate time reading.

Maintenance SOP example

When structuring your maintenance SOP documentation, the best point of reference is your equipment manuals and using your current staff of experts for feedback and suggestions. Your team will know the most efficient and accurate way to complete a task that can further be finessed and formatted into a formal SOP.

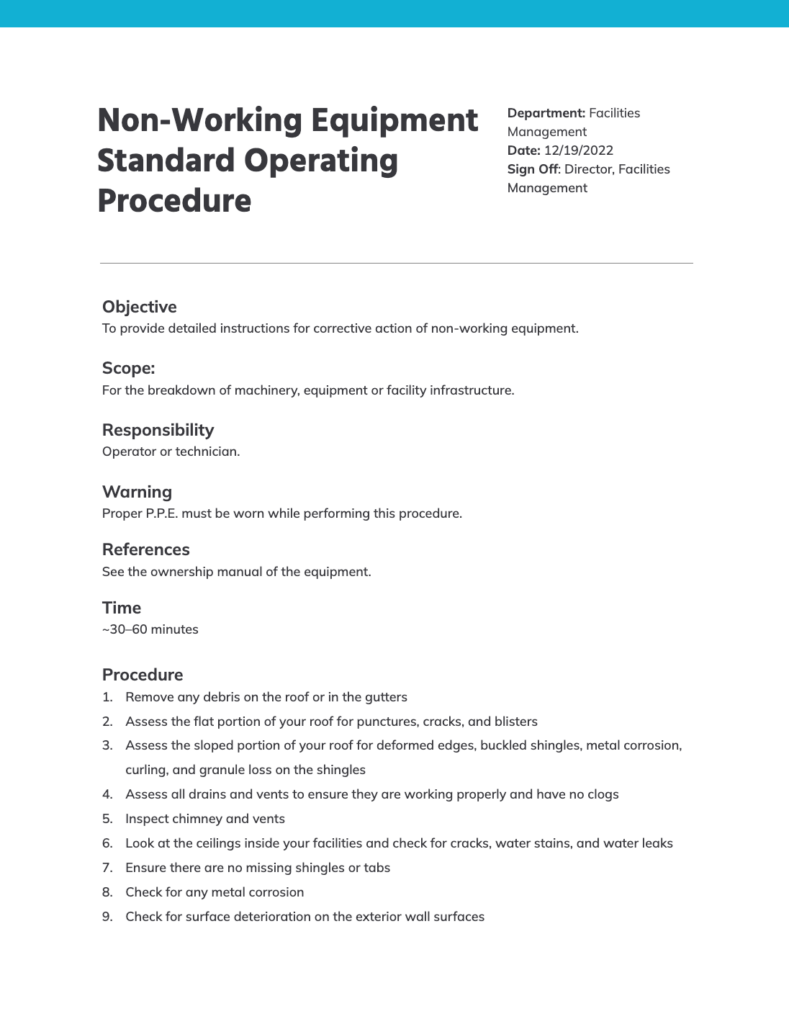

To help you more fully understand how to write a maintenance procedure, you can use our Maintenance SOP example as a template.

Maintenance management and planning with FMX

By integrating your SOPs into managed maintenance management software, you can guarantee that every procedure is within reach for quick reference and quality assurance. Easily align guidance with scheduling and other maintenance operations and achieve streamlined work order management, preventive maintenance and asset tracking.

Optimize your facility management even further with FMX’s free, downloadable preventive maintenance checklists to help your team check its progress as they complete various work orders.

Reach out for a free demo of our maintenance management software today.

Written by

Dana Grove

Manager, Brand and Content at FMX