Solution overview

Key capabilities

- Asset tracking

- Work order management

- Preventive maintenance

- Floorplan visualization

- Capital planning & forecasting

Extend the life of your assets

Increase asset performance and extend the value of your investment through reliable maintenance and service schedule.

Minimize unplanned downtime

Keep your machines running longer and resolve issues quickly with effective preventive maintenance and work order management systems.

Maintain safety and compliance regulations

Preserve a documented history of work completed, with standardized inspection checklists to reduce liability and risk.

Gain confidence in your capital planning

Track condition assessments and maintenance costs for each of your assets to strategically plan out replacement dates.

FMX equipment maintenance management software capabilities

Inspection checklists

Create step-by-step instructions for all your inspections, cleanings, and QA testing.

Centralized calendar

View reactive and proactive work all in one central calendar, with the ability to filter down based on your needs.

Automated assignment

Save time and resolve work faster by automatically assigning the technician best suited for the task.

Inventory management

Track spare parts and consumables to always see the remaining inventory left in stock.

Cost and labor tracking

Record total cost and time spent on each maintenance activity to view summary reports.

Downtime tracking

Trigger equipment downtime and uptime, and view total downtime summaries to inform decision-making.

Reporting & analytics

Leverage auto-generated reports to view costs, inventory usage, completion rates, and other key metrics.

Vendor & contact management

Keep a directory of vendors, suppliers, and outside contacts for quick reference.

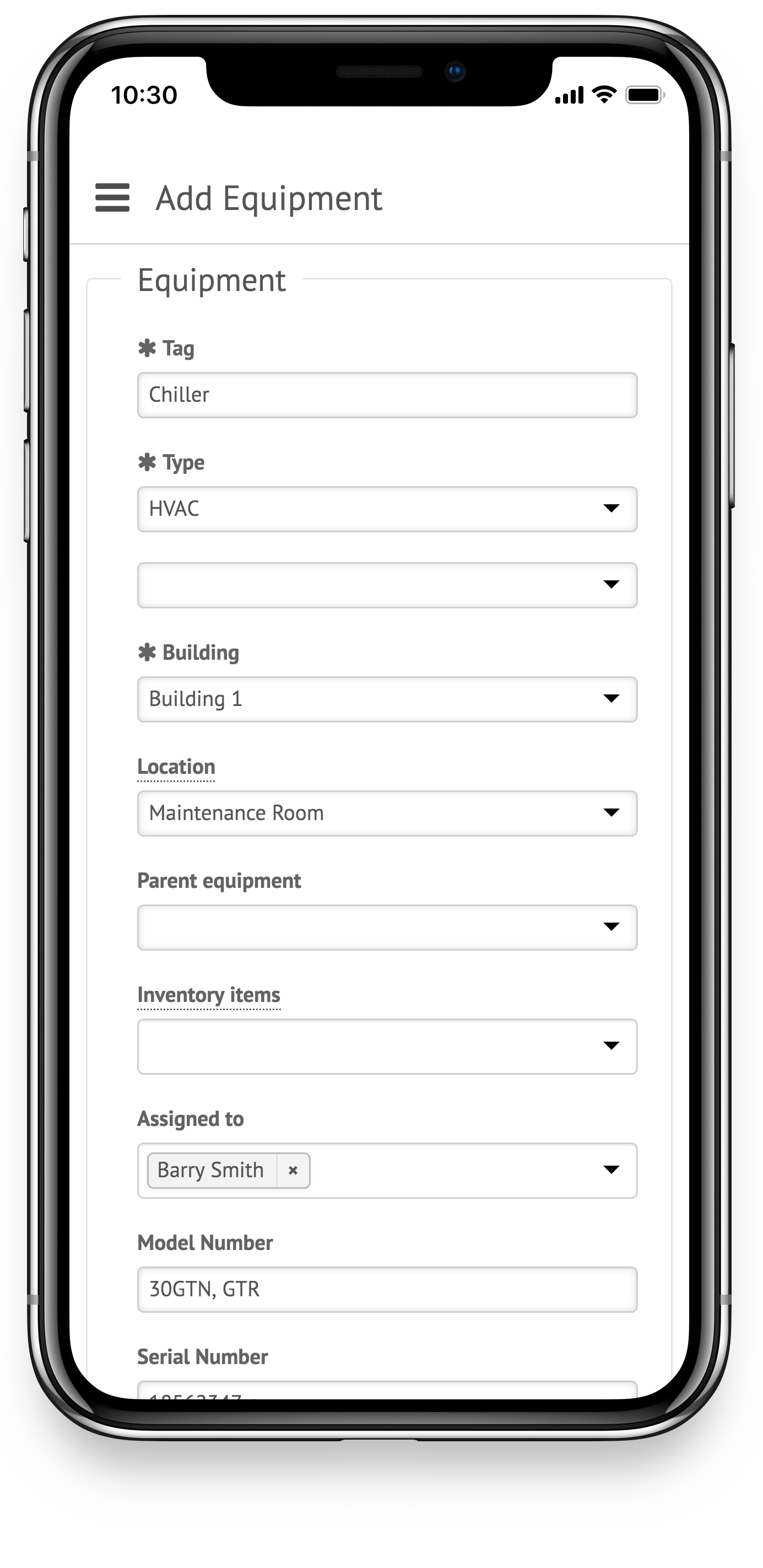

Full mobile access

Access the full FMX product on the go from your phone or tablet.

API integrations

Connect FMX with your other operational software through pre-built integrations or access to a REST API.

See all of FMX's asset maintenance capabilities in action

See it for yourself

Stop the leaks in your operating budget with a maintenance process you can count on.

Related use cases

Maintenance Management

Schedule work, track assets, and leverage data-driven insights to optimize your operations.

Work Order Management

Streamline maintenance request submissions and resolve issues while keeping track of labor hours and money spent.

Preventive Maintenance

Keep your operations running smoothly with a reliable preventive maintenance and inspection system.

Asset Mapping

Create a visual paradigm of your organization's equipment, inventory, resources, buildings, users, and other assets.

Inventory & Supply Management

Track usage, manage purchase orders, and get data insights into historical trends to optimize your inventory & supply management.

Capital Planning

Create capital plans, manage budgets, back up future capital investments, and schedule preventive tasks to ensure equipment longevity.

Reporting & Analytics

Capture, analyze, and discover actionable insights to optimize your organization's operations.

Thousands of maintenance managers and technicians rely on FMX for asset and equipment maintenance

FMX gives me capabilities I never had before. Now I can look at the equipment in each of our restaurants and verify the frequency and cost of every repair. Because the recordkeeping is so comprehensive, I can determine when a particular piece of equipment is no longer cost-effective and should be replaced.

$33K equipment cost savings in the first 3 months

Lowers overhead by finding the sweet spot for equipment replacement.

The reporting feature has really improved our distribution of costs and accurately tracking our costs across the plant. It also helps us with capital projects. We can see how much money and time we're spending on equipment, and if you don't have that data, it's very difficult to justify capital projects.

The reporting has probably been the greatest thing to ever happen, according to the corporate office.

Gains the insights needed to make strategic decisions and plan for the future.

All CMMS systems are going to have similar functionality—take requests, monitor equipment, schedule preventive maintenance, etc.—but FMX is by far the easiest to use and their amazing customer support sets them above the rest.

50% reduction in work order resolution time

Resolves issues faster with an organized, easy-to-use system.

Benefits of equipment maintenance software

Benefits of equipment maintenance software

- Extend your equipment lifespans

- Minimize unplanned downtime

- Lower work order resolution times

- Reduce risk and liability

- Inform capital planning

Making the switch is easier than you think.

Allow us to handle the heavy lifting.

We work with your team to transfer existing data and build workflows to meet your needs.

Empower your team with an easy-to-use platform.

FMX is built with simplicity in mind, so anyone can use it and be successful.

We're here to help along the way.

Our team is here to train your organization, with lifetime support to answer your questions.

![[A/B Test] Equipment Maintenance Laptop Demo vs. Product Tour](https://www.gofmx.com/wp-content/uploads/2020/02/equipment-maintenance-feature-video-thumb.jpg)